Price: Call

Walnut sand carbon cleaning machine CERES CE-300.1400

.jpg)

Automobile walnut sand carbon cleaning machine is used through the intake pipe valve cleaning machine to clean the engine intake tract carbon advanced equipment.

Through the high-pressure airflow sprayed into the engine intake duct, high-pressure and high-speed sand particles will tumble and crash in the closed intake duct, so that the intake valve and cylinder wall of the Then the walnut sand and carbon mixture will be recycled to the sand storage barrel through the special connector to maintain the health of the engine. Then the walnut sand and carbon mixture is recycled to the sand storage barrel to keep the engine in a healthy state and ensure that the engine continues to provide high-quality power.

What is Walnut Sand?

The raw material of walnut sand is a walnut shell, which is made and synthesized through strict screening and classification and multiple processes after the walnut shell is broken. It is a walnut extract and belongs to metal polishing media. It has the characteristics of high hardness, high-pressure resistance, and wear resistance, and the surface is microporous. It has strong adsorption and sewage interception ability, no corrosion and no pollution. Walnut shell is a natural and non-chemical raw material, so using walnut sand as an abrasive will not damage the surface of the workpiece, and using walnut sand to clean auto carbon deposition will not damage the engine, the cleaning effect is remarkable and the cost is low.

What is carbon deposition?

There are some hydrocarbon olefin residues attached to the engine intake, cylinder when the fuel burns in the engine not completely. It residues change into a hard black shell in high-temperature conditions, called carbon deposition.

Why need Clean Carbon Deposition?

Carbon deposition will decrease the air-fuel ratio, cut down engine output power, increase fuel consumption, engine drastic shake on idle status all the thing will hurt the engine deeply. So normally we should clean carbon deposition after every 40000-50000 kilometer trip.

CERES CE-300.1400 Features

External air source: This enables the walnut sand grit to strike the carbon deposits more powerfully and efficiently.

Integrated design: The walnut sand grit can be sprayed and recovered simultaneously.

Built-in dust filter: It can separate the recovered walnut sand grit from carbon deposits for recycling.

Deep removal of carbon deposits: Deeply removes the highly sticky carbon deposits on the intake manifold, intake & exhaust valves. (Solve the problems of unstable idling, insufficient fuel combustion, and reduced air-fuel ratio.)

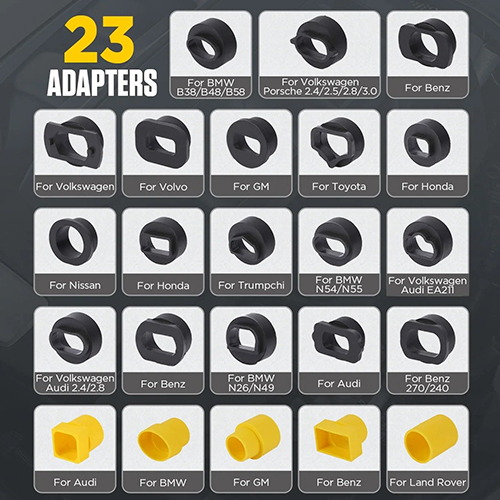

Multiple adapters: Equipped with 23 kinds of adapters, suitable for a variety of models, such as BMW, Volkswagen, Mercedes-Benz, GM, and VOLVO.NISSAN and so on.

3-year warranty: For damage caused by non-human factors, we promise to resend parts for free within 3 years.

How To Use the CERES CE-300.1400?

Step 1: Open the headcover of CERES CE-300.1400 and pour it into walnut powder (need 2- 4KG ), press dust guard on walnut powder then close the cover.

Step 2: Join the spray gun muzzle and recycle the hose together. (there is a hole in the recycle hose)

Step 3: Remove the intake manifold of the engine, plug the spray gun into the intake, and turn the crankshaft to close the intake valve. Then connect the high-pressure air pump((not included)) to CERES CE-300.1400.

Step 4: Connect AC power, and start clean. The process should last 1-3 minutes. (depending on carbon deposition circumstances)

Step 5: Close CERES CE-300.1400, check cleaning result. Normally, the walnut powder can be reused 5-10 times. (depending on carbon deposition circumstances)

.jpg)

Others

Engine Combustion Chamber Cleaning Machine Using Oxyhydrogen Technology Kawasami KCS1000

Price: Call

1866 viewer

Share

Share