TECHNO VECTOR 7 P 7204 TAS

DESCRIPTION

|

Model |

V 7204 T A |

|

Manufacturer |

TechnoVector Group |

|

Made in |

Russian |

|

Number of cameras |

4 stationary cameras |

|

Camera type |

2x1.3MPix and 2x5MPix machine vision industrial cameras, RAW |

|

Mounting type |

Floor-mount. T-shaped pillar |

|

Cabinet type |

V-series |

|

Applicability |

Lift or Pit |

|

Distance from cameras to the center of front turn tables |

1200-2550mm, recommended distance 2200mm |

|

Main advantages |

|

* Only when taking measurements in the plane of a vehicle. To take measurements relative to the horizontal plane it is necessary to perform horizon measurement.

** When installed at the distance of more than 2200mm from front turn tables, the wheel aligner works from the lowest position of the lift up to the height of 1700mm.

INSTALLATION AND CALIBRATION

|

Mounting |

Required (floor) |

|

Calibration after mounting |

Not required* |

* Only when taking measurements in the plane of a vehicle. To take measurements relative to the horizontal plane it is necessary to perform horizon measurement.

Installation and calibration must be performed by a certified specialist.

This wheel aligner is supplied pre-calibrated and can be used right after installation.

I. DESCRIPTION

TECHNOVECTOR WHEEL ALIGNERS WITH 3D AND WIDESCOPE TECHNOLOGIES

- TechnoVector 3D is a new generation of wheel aligners that includes all the latest innovations and technologies.

- Machine vision system includes 2 or 4 cameras.

- The key advantage is the WideScope technology which is unique in the world.

- Thanks to WideScope the operational range of the heights f the lift is twice as big as that of similar wheel aligners produced by other manufacturers.

- Measurements can be performed at the floor level*.

- Techno Vector 3D wheel aligners are designed to take measurements and make adjustments on steerable and unsteerable axles of cars and can be installed in automotive companies, tire shops, car service stations, automotive manufacturing plants, diagnostic centers.

- The wheel aligner performs measurements by observing high-precision image targets, that are placed on the vehicle. It calculates their precise positions in 3D space and using simple procedures, such as compensation and measurement, calculates all the wheel alignment angles.

* - When installed on a lift applies only for 4-camera wheel aligners when installed at a distance of 2200mm or more.

TECHNO VECTOR 3D WHEEL ALIGNMENT SYSTEMS INCLUDE THE FOLLOWING BASIC PARTS:

1. Computer console:

- ergonomic operating control panel;

- color inkjet printer;

- full-size keyboard;

- mouse;

- membrane keyboard duplicating main functional keys*;

- remote control reciever;

- 21.5" color widescreen LCD monitor;

- TechnoVector 3D software.

* - V-series of computer cabinets only

2. Self-centering clamping arms:

- Self-centering clamping arms fit 12" to 24" rims and are compatible with motor car rims and light truck rims.

3. Targets:

- Do not contain any electronic components;

- High-quality photomasked images to maximize the wheel aligners precision;

- Surfaces are covered with a protective oil-and-petrol resistant layer;

- Very durable and impact-resistant housing.

4. Machine vision system:

- Different versions of housings allow to choose a wheel alignment system configuration to match with customers requirements;

- Floor-mount and wall-mount configurations are available;

- Drivethrough can be set up for floor-mount aligners;

- The machine vision system is equipped with precision LAN camera units based on big and high-quality image sensors;

- Data transfer from the camera units to the PC uses a standard TCP/IP protocol. This allows to use both wired and WiFi camera configurations with ease;

- WideScope - a unique "wide-angle" machine vision system makes it possible to increase the range of working heights to twice as much compared to similar wheel aligners of other manufacturers.

5. Techno Vector 3D software:

- Supports Microsoft Windows 7, 8 and 10;

- The 3D model of the car chassis allows you to see position and wheel alignment angles on the screen in real-time;

- User friendly interface and advanced Help and Support System allow even novices to learn how to use the wheel aligner quickly and to start working.

6. Accessories package.

(link video youtube)

II. FUNCTION

The computer-based wheel alignment system is a measuring device designed to control basic parameters of axis positions in any types of motor cars with 12" to 24" rims.

TechnoVector 7 is designed to take measurements and make adjustments on steerable and unsteerable wheels in automotive companies, car service stations, auto sales centers and dealer diagnostic centers.

The device allows measuring the following basic parameters:

-

Front and rear axle:

- total and individual toe angles;

- camber angles;

- wheel set-back;

- axis symmetry angles.

-

Front axle (steerable wheels):

- caster angle;

- SAI/KPI.

III. PRODUCT CODE GUIDE

|

V |

7 |

2 |

0 |

4 |

Т |

5 |

А |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

1 - Letter specifying a computer cabinet series: T, V.

2 - A number indicating the device series (7 for Techno Vector 7).

3 - The number of axles measured simultaneously.

4 - The video camera movability: 0-stationary, 1-movable.

5 - Total number of video camera units in the modification: 2,4.

6 - Letter specifying the video camera housing type: T, K, H, M.

7 - Camera sensor resolution: 1 for 1.3Mpix, 5 for 5Mpix.

8 - Letter specifying the design of the video camera housing: Premium, Aluminum.

IV. DELIVERY SET

Computer cabinet V- Series

The computer cabinet V-series is a more ergonomic construction with an extra membrane keyboard and a shelf for a full-size keyboard.

TECHNOVECTOR 7 ACCESSORIES (BASE CONFIGURATION)

|

Machine vision system |

1 |

|

Computer cabinet (as a unit) |

1 |

|

Electronic unit |

1 |

|

Target set |

4 |

|

Self-centering clamping arms |

4 |

|

Steering wheel holder |

1 |

|

Brake lock |

1 |

|

Turnplate |

2 |

|

Remote control receiver |

1 |

|

Remote control |

1 |

|

Manual |

1 |

|

Color ink-jet printer |

1 |

TechnoVector Group keeps working on equipment modernization. Therefore the manufacturer reserves the right to make changes in equipment without notice for making progress and improving characteristics.

V. SPECIFICATION

|

Parameter |

Measurement Range |

Maximum |

Average |

|

Front Wheel Alignment |

|||

|

Camber |

+/-8º |

+/-3 |

+/-2 |

|

Front Total Toe |

+/-5º |

+/-3 |

+/-2 |

|

Caster |

+/-19º |

+/-8 |

+/-5 |

|

SAI/KPI |

+/-19º |

+/-8 |

+/-5 |

|

Lock Angle |

+/-45º |

+/-10 |

+/-5 |

|

Rear Wheel Alignment |

|||

|

Camber |

+/-8º |

+/-3 |

+/-2 |

|

Rear Total Toe |

+/-5º |

+/-3 |

+/-2 |

|

Rear Individual Toe |

+/-2,5º |

+/-3 |

+/-2 |

|

Symmetry Angles |

|||

|

Front Set Back |

+/-2,5º |

+/-3 |

+/-2 |

|

Rear Set Back |

+/-2,5º |

+/-3 |

+/-2 |

|

Thrust Angle |

+/-2,5º |

+/-3 |

+/-2 |

|

Geometrical Driving Axis |

+/-2,5º |

+/-3 |

+/-2 |

|

Parameter |

Value |

|

Voltage, W |

220 +/- 10% |

|

Frequency, Hz |

50/60 |

|

Wheel Adapter (clamping arm) Mounting Range, in. |

12 ÷ 24 |

|

Operating Temperature, oC |

+10 ÷ +35 |

|

Power Consumption |

350 |

|

Net Weight, kg |

280 |

|

Gross Weight, kg |

390 |

|

Volume, m3 |

1,7 |

|

Number of Packages |

7 |

|

Climatic category of the Device according to GOST (All-Union State Standard) |

GOST 15150-69 |

VI. Widescope

Key features of the WideScope technology :

- The range of working heights of the lift is up to twice as much as similar wheel aligners of other companies.

The 4-camera wheel aligner makes it possible to take measurements and make adjustments on the lift from the alignment height (1700 mm) to the floor level without using any camera displacement mechanisms, stairs and stands.

The 2-camera wheel aligner makes it possible to take measurements and make adjustments on the lift in the range of lift heights of 900-1700* mm from the floor level.

- Minimum distance (from 1200 mm) from camera units to the lift or pit in comparison to similar wheel aligners of other companies.

Minimum requirements for the size of the workshop - 6550 mm.

- Long-range capability video camera housings can be installed at a long distance. It is especially important for wall-mount configurations when the wall is far from the workplace (3-4 meters).

- Operation can be carried out even when the target image is partially closed or damaged!

* depends on the distance of the camera housing placement

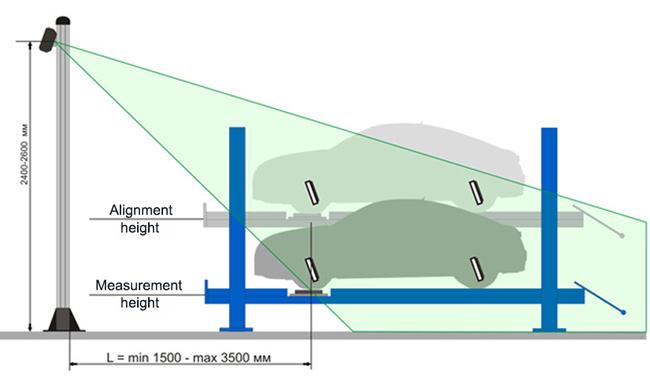

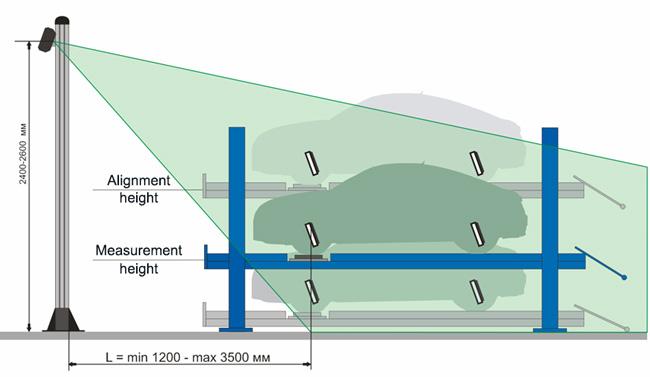

Camera vision range diagrams for the WideScope TechnoVector wheel aligners

TechnoVector 7204 installation range

* - for wall-mount configuration (type K).

** - camera characteristics differ for 1200-2550mm range and 2550-3500 mm range, if the distance is more than 2550, the measuring height increases.

TechnoVector 7202 installation range

* - wheel aligner camera makes it possible to take measurements on the floor level without using any camera displacement mechanisms, stairs and stands if the distance L is more than 2700mm.

VII. TECHNO VECTOR 3D SOFTWARE

Techno Vector 3D Software Features

3D Visualization

·

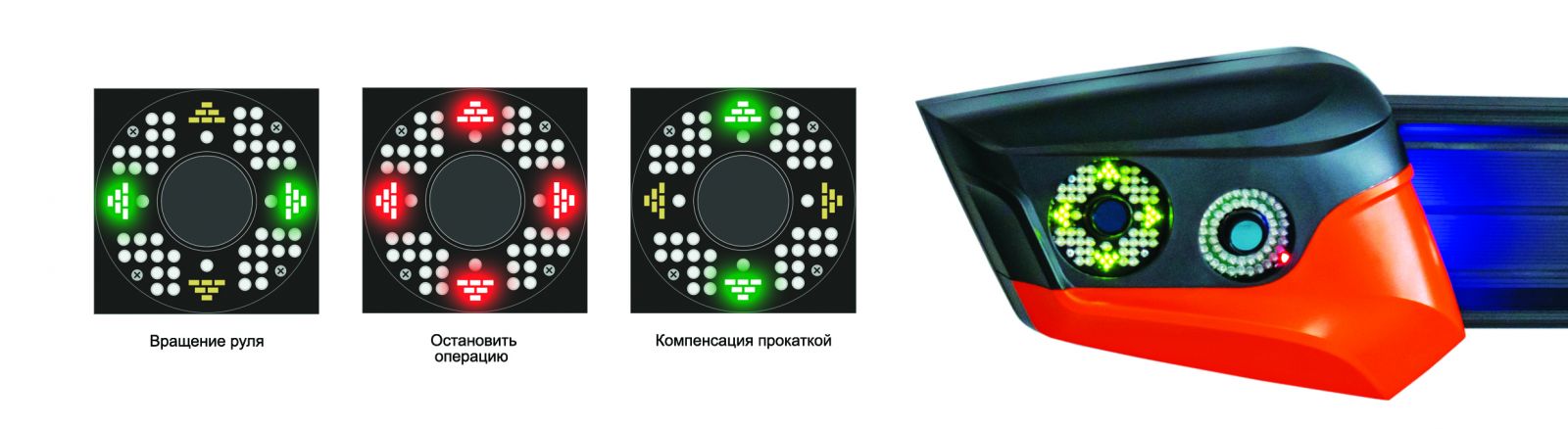

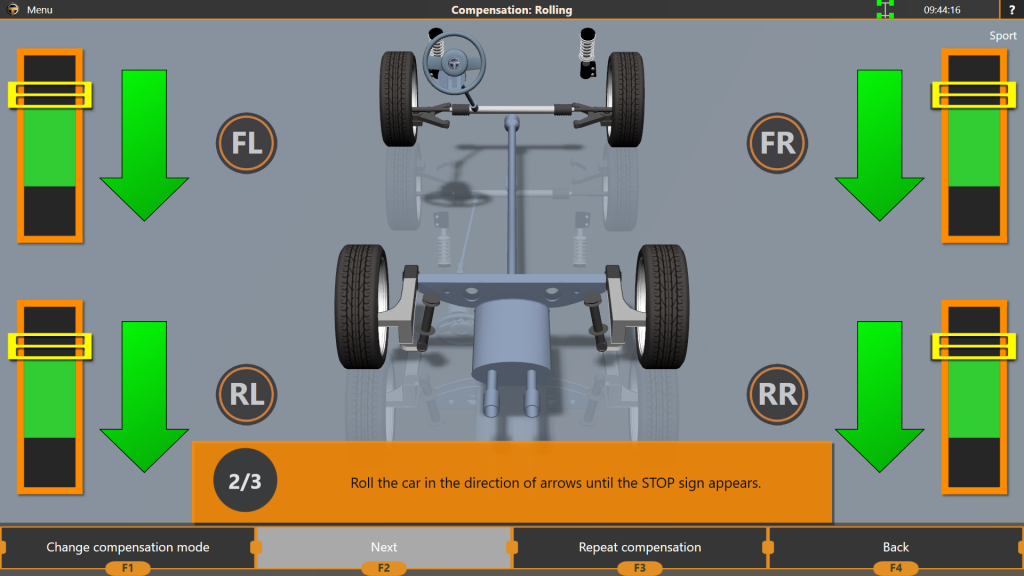

Compensation screen

· The software features an animated 3D model of a generic car chassis

The wheels are positioned according to measured values of toe, camber and caster

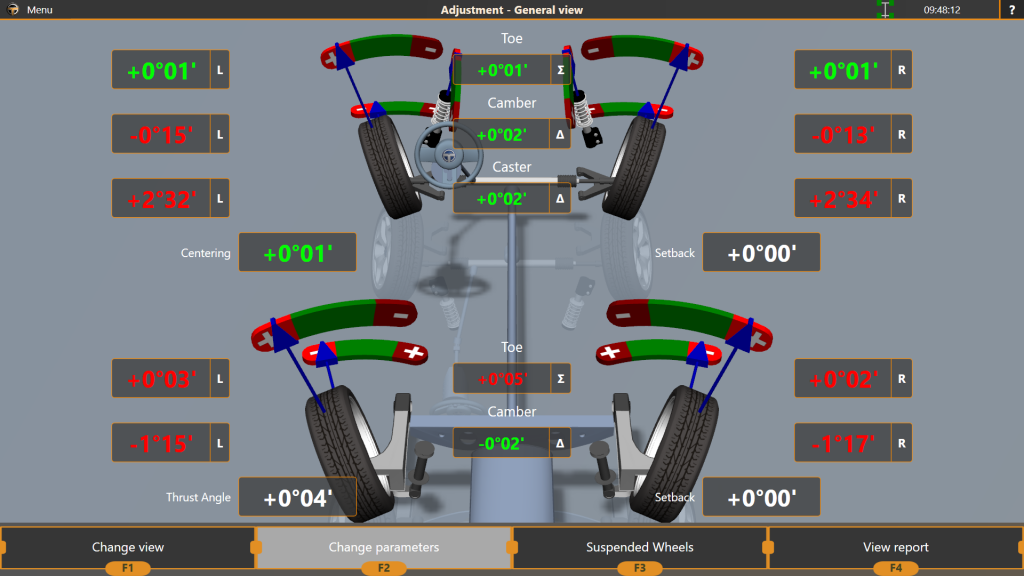

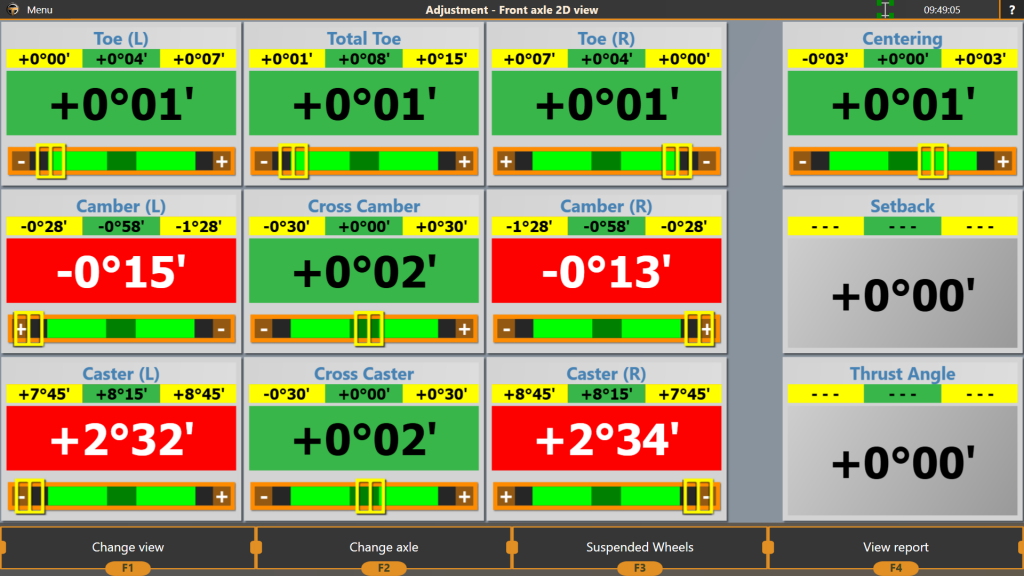

The adjustment mode features several views: for each wheel, for each axle, general view, geometry view and a 2D mode

3D gauges are displayed on the screen during the adjustment. They allow a better visualization of measured wheel alignment values

All the information on the screen is updated live in 3D

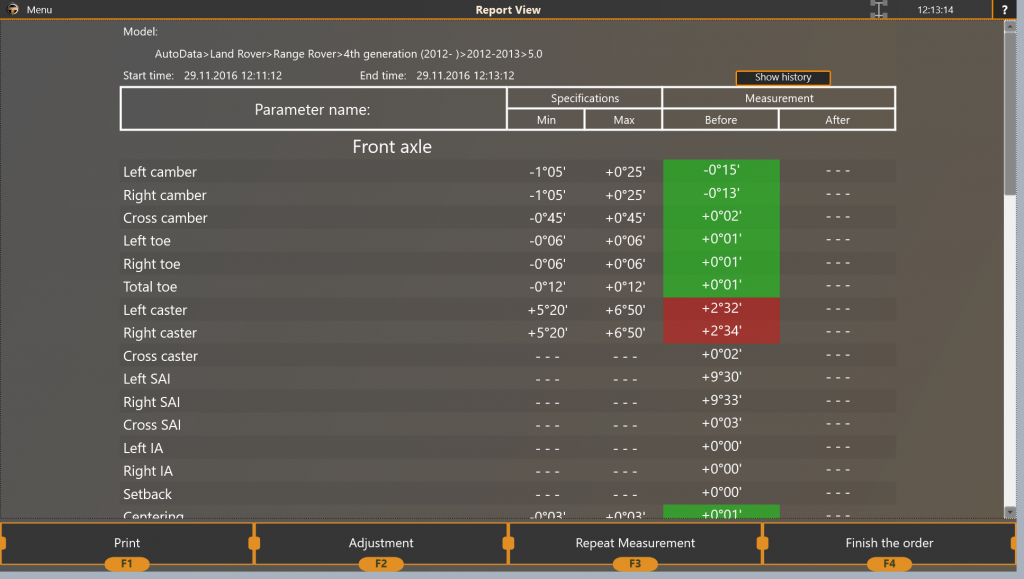

Print-outs generated by the software can also include 3D rendered images illustrating positions of wheels before and after the adjustment

Cutting edge technology

·

·

Adjustment screen - Main view

· Extremely fast refresh rate of the measured values. Cameras can shoot up to 40 frames per second and the software keeps up with them

Detects partially occluded targets*

Multiple pass target detection allows working at extremely bright workspaces

Multithreaded architecture utilizes all the capabilities of modern multi-core processors

DPI-independent software scales correctly on every modern display including 4K monitors**

Fast transition time. All the screens are preloaded at the start to ensure that there are no pauses while navigating.

Extensive car model database is also preloaded right when the software starts and provides instant response time when searching or navigating

Measurements

·

·

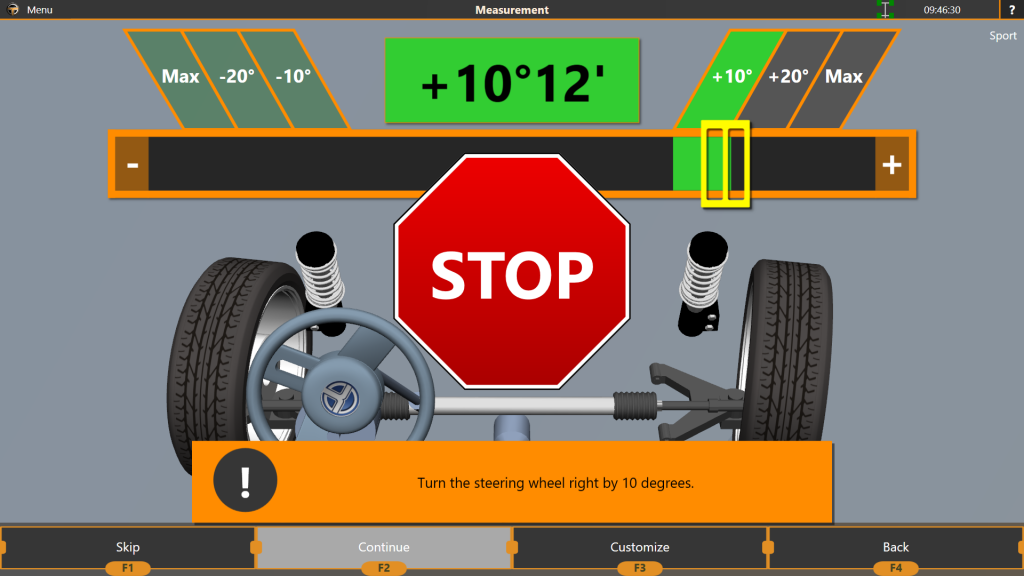

Measurement screen

· The software employs all the modern techniques to improve the precision of calculating targets positions in 3-dimensional space

Multiframe smoothing reduces data instability due to vibrations, lighting conditions, yet swiftly reacts to any bigger changes

The software can automatically detect lift movement during adjustment and correct the live values if the lift skews at the adjustment height

Two measurement coordinate systems are supported: calibrated horizon and vehicle plane*

Hanging wheels mode allows adjusting car parameters with wheels jacked or turned to ease the adjustment.

* Horizon measurement is unavailable on non-stationary wheel aligners

EASY AND CUSTOMIZABLE WORKFLOW

Adjustment screen - 2D view

· Intuitive workflow that utilizes only four buttons at the bottom of the screen

Helpful images are shown to remind the aligner technician of actions that need to be performed

The software stores all orders and all measurements. They can be reviewed at any time.

The software stores history of all calibrations. The results can be reviewed at any time.

All the navigation through most of the software can be done using hotkeys on remote control or the keyboard

Web-camera support allows to display web-camera feed in main menu to help the driver to position the vehicle on the workplace.

Multiple settings allow to fine tune the behaviour of the softwares interface. Possible options include:

Print-out setup allows to select one of two templates and to set up texts and logos as well as several other useful options

Automatic transitions are available where possible. For example, the software automatically detects when the compensation starts and proceeds to the next step.

The user can select default modes for compensation, measurement or adjustment

Several other fine-tuning for adjustment, compensation and measurement modes

DATABASE

·

·

Model selection screen

· Contains more than 65000 vehicles

Vehicle entries contain information, images and videos on identification and preparatory procedures and on how to adjust camber, toe and other values

Free database updates

Allows to add an unlimited amount of custom models and to export/import them (especially good for brand-new car models and for markets with local car manufacturers not yet present in our database)

OTHER FEATURES

·

Report screen

· Statistics screen displays valuable information about wheel aligners productivity: how many adjustment were made over a given period, what was the average adjustment time, etc.

Tire pressure tables are available for most of the models in the database

Easily export order data to Excel or other e-table software with Export to CSV function ASA Network support.

The TechnoVector 3D software works with Windows 7, Windows 8 and Windows 10.

Others

Share

Share